robert campbell

Well-known member

- Joined

- Apr 10, 2007

- Messages

- 4,322

All,

I finally wrestled Sheryl’s carb for Gem her 1968 Big Block 390 automatic GT/CS to the ground. Had to get a thread repair kit for the needle and seat hole in the float bowl. Got that done and if anyone has a stripped float bowl, I can fix it.

Well, I performed a few tricks to get it better, but to no avail. It idled like crap and had a large flat spot off idle. Just like before even after the secondary idle discharge port enlargement from .022 to .028 in diameter per the Ford TSB bulletin. I could close down the idle screw on the driver side and kill the engine. The passenger side had no effect. I could tell that the driver side was compensating for the passenger side. Ok engine vacuum, but not steady and a noticeable miss on the right back of the engine. Crap!!

Back off for the 3rd time. Off with the front metering block. Cleaning and blowing out all passages yet again. All seemed clear and was about ready to remove the soft plugs and disassemble the emulsion tubes from the metering block which I have never had to do before.

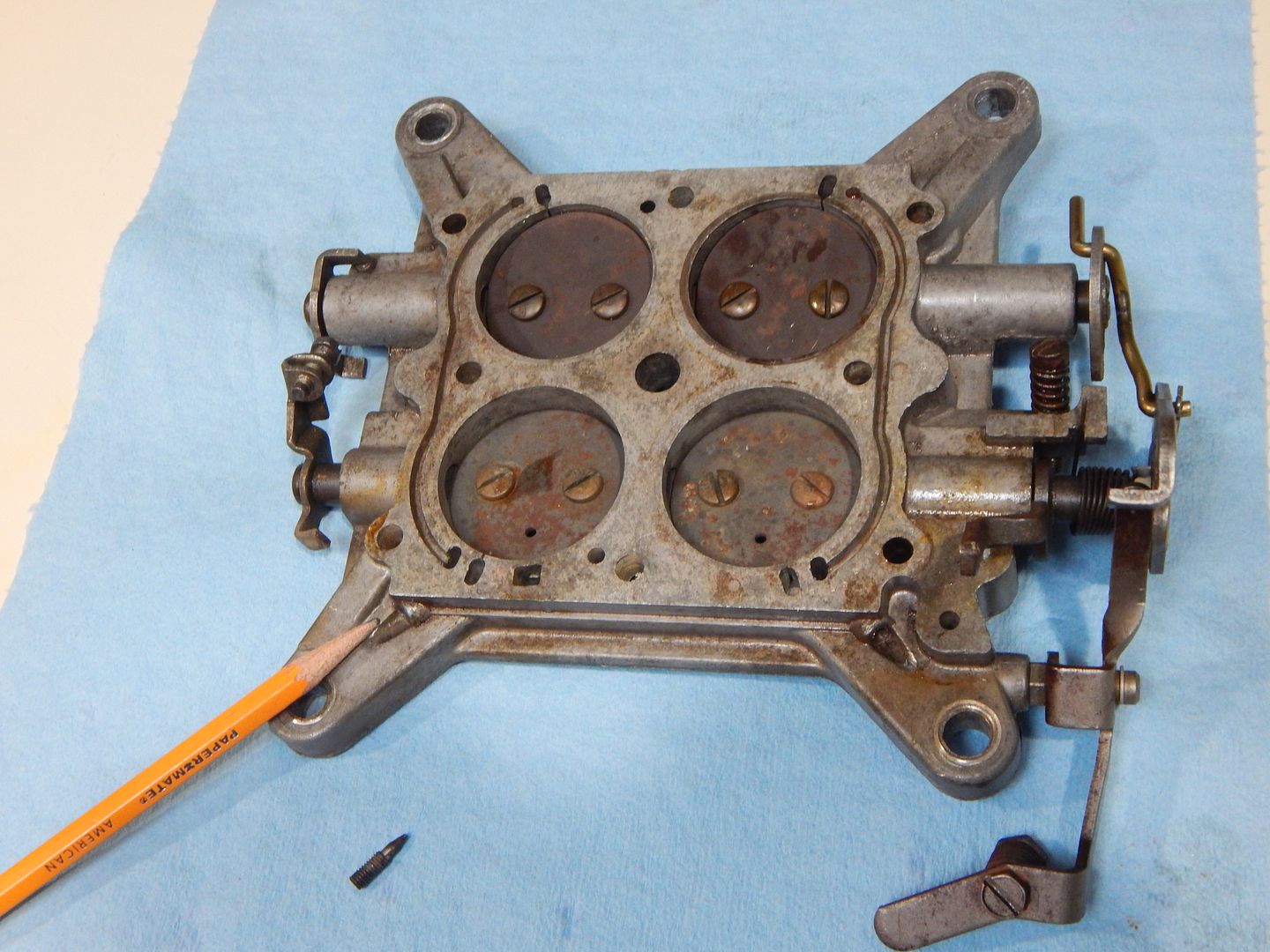

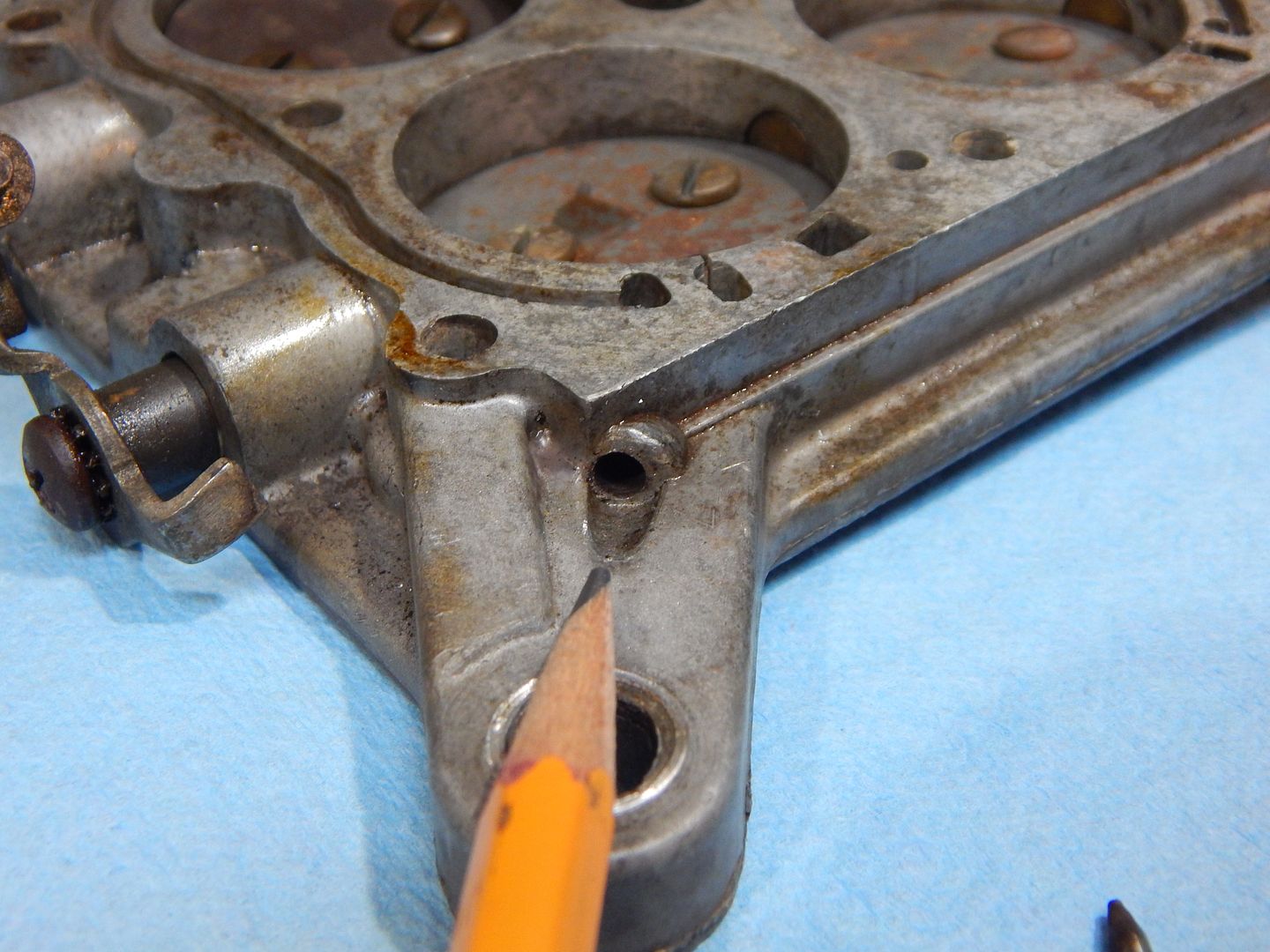

Started to inspect the transfer slots and the idle discharge port in the throttle plate assembly. Got out the magnifying glass and low and behold. This 1968 era Holley has a second set of idle mixture screws and someone had completely closed down the passenger idle discharge port by running the air mixture screw in and bottomed. I have sent this to the Holley tech line and they have never seen this before. Of course it is a tiny screw and stuck from sitting all these years. Out with the blow torch and the Kroil and with some patience I got it unstuck and screwed it out to the same depth as the driver side.

Below are some pictures of this secondary port on these old Holley’s. I would like Dan and Eric to see if they can take a picture of their throttle plate to see if they are there also on their carbs. I bet they are and I learned yet another idiosyncrasy of these carbs.

Sheryl’s carb runs like butter now!! Check out the link and hear it run!!

Rob

https://www.youtube.com/watch?v=xbgc6q5XZ-Q

Marty's new HCS big block has the same screws that I found on a couple other 390 Holley 3795 carbs. His screws came out way easier than Sheryl's did!! Hope to get the Cougar out soon and dial this thing in for Marty. We have a foot of snow on the ground.

Rob