Arlie/Steve,

Why yes I did on the driver seat question. Although, your Shelby is like a freight train and the power just keeps coming. Impressive!!! And from a small cubic inch motor!!

All of the posts are spot on about “over” carbureting. Many a person has done this and a carb is just a piece of the total package. Gear ratio, tranny type, headers, cam shaft, car weight, and so on. I love to help people with a package in total that is designed with their ultimate goal in mind. And if this package is built over a few years a dollars are available, I like to recommend each step in a sequence along the way. And in an order of purchase and installation that does not degrade performance along the way. And with that, the larger carburetor can be one of the last steps. Trust me none of this is not known by Steve!! He knows this as well as I do.

To address the question of a larger carb and smaller jets it always boils down to one factor. A venturi size that produces maximum airspeed through the carb at, or near, the maximum torque of the engine. A stock 289 or 302 falls in the max torque from around 2,500 to 3,200 RPM depending on the 4 barrel or 2 barrel version. 302 cu in engine 2 or 4 barrel is right in the middle at 2,800 RPM.

Air speed through the carb at the proper RPM is everything. Air speed ensures proper mixing of the air and gasoline discharge. The venturi effect is what draws the fuel up and out of the float bowl. A larger carb with larger venturies will create slower air speed at lower rpm on these stock engines and create a noticeable “bog” at just the time the engine hits its designed maximum torque. The larger carb actually hinders performance across the board. Now I am talking about a stock engine and stock configured car with say a 650 to 700 CFM carb. Add lower gears and the bog starts to disappear a bit. Add other performance items and yee haa.

So reducing main jet size and only opening to partial throttles will help little. Main jet reduction may help a “bit” but the venturi size is the main factor. Slow air, poor gasoline atomization, at the wrong RPM, equals crap performance and poor gas mileage. And the large carb has a larger idle circuit capacity that drives you out of the garage with burning eyes. Bad all around.

The small 4100 Autolites and 500 CFM Edelbrock are my favorites on stock 4 barrel cars in stock configuration. The 1968 Autolite 4300 seems a bit more temperamental than the 4100, but still a great choice. A 600 CFM Holley or Edelbrock is a good choice if you have a a couple things like shorty headers or K code exhaust, and a mild cam.

Of note, Pony carbs had a neat little add on for the 4100 Autolight. They made some “slip in” plastic venturies for the primary side that increases the air speed even more than a stock 4100. Better gas mileage yet and a bit of tuning on the secondary produces the same performance with better performance across the entire power band. A great add on if you can find them. Pony is out of business I have heard. This add with a couple mods was a great upgrade that Pony offered.

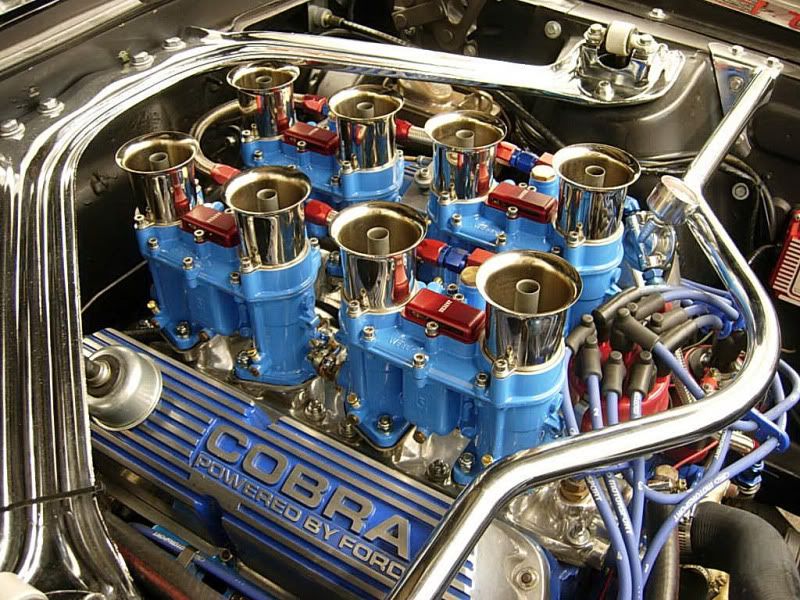

Now the Weber’s on Val’s 289 are part of a total package with 13 to 1 compression and huge valves and intake and exhaust porting. Giant solid roller cam that coupled with the rest demands lots of CFM even at low RPM. Low gears and headers. And 7,500 RPM redline. The venturies (Weber calls them chokes) are sized for the application. Weber venturies are removable! This system with the 8 throttle plates about two inches from the intake valve produces crisp throttle response and low end power that rivals any big block. The ability to exchange venturies of different sizes is why the Weber’s were so popular back in the day. All aspects of the air mixing from emulsion tubes to main jets were accessible without removing the carb form the engine. Made them infinitely adjustable for altitude changes and different sized engines or bores and strokes. Pony Carbs used this theory above!!

Rob